Designing a Submarine

The most notable feature of our ROV is the pneumatic claw, situated front and center on the submersible. The claw’s main mechanism, including the grippers and the body, is made of laser-cut acrylic. The material was chosen for both its price and sturdy quality, over wood or 3d printed options. The mechanism is then attached to a pneumatic actuator, which gives the opening and closing function of the claw. That actuator is then attached to a pneumatic rotator, which has the capability of rotating the claw 90 degrees to allow for a horizontal grab on an object. This rotator then attaches to the frame of the submarine.

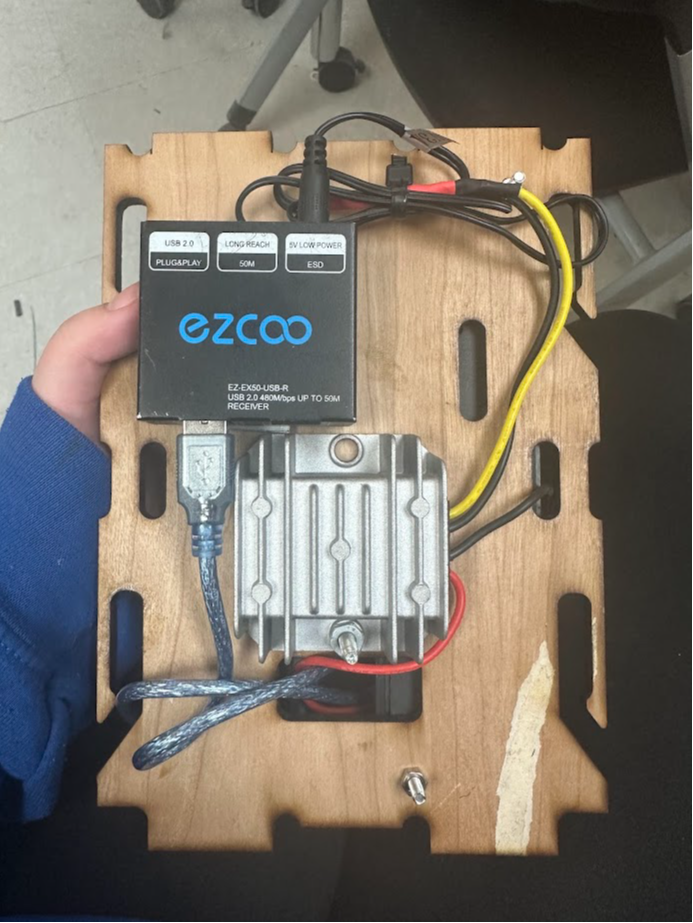

All of the in-water electronics are housed inside a tightly sealed acrylic tube. Then, from that housing, a tether runs pneumatic hoses, for the claw, power, ground, and an ethernet cable to the shore. This tether then connects to our on-land control box. This control box is, of course, used to control the entirety of the submarine.